Did you know the average U.S. office wastes up to 23 minutes every workday wrestling with printer issues? That’s nearly two hours a week of lost productivity you could reclaim. Understanding what’s under the hood (and inside the trays) is step one.

Whether you manage a bustling enterprise fleet or run a lean home office, this glossary demystifies the moving pieces—and consumables—of your printer, so you can fix hiccups faster, buy smarter, and print jam‑free.

Printer Parts: The Essentials

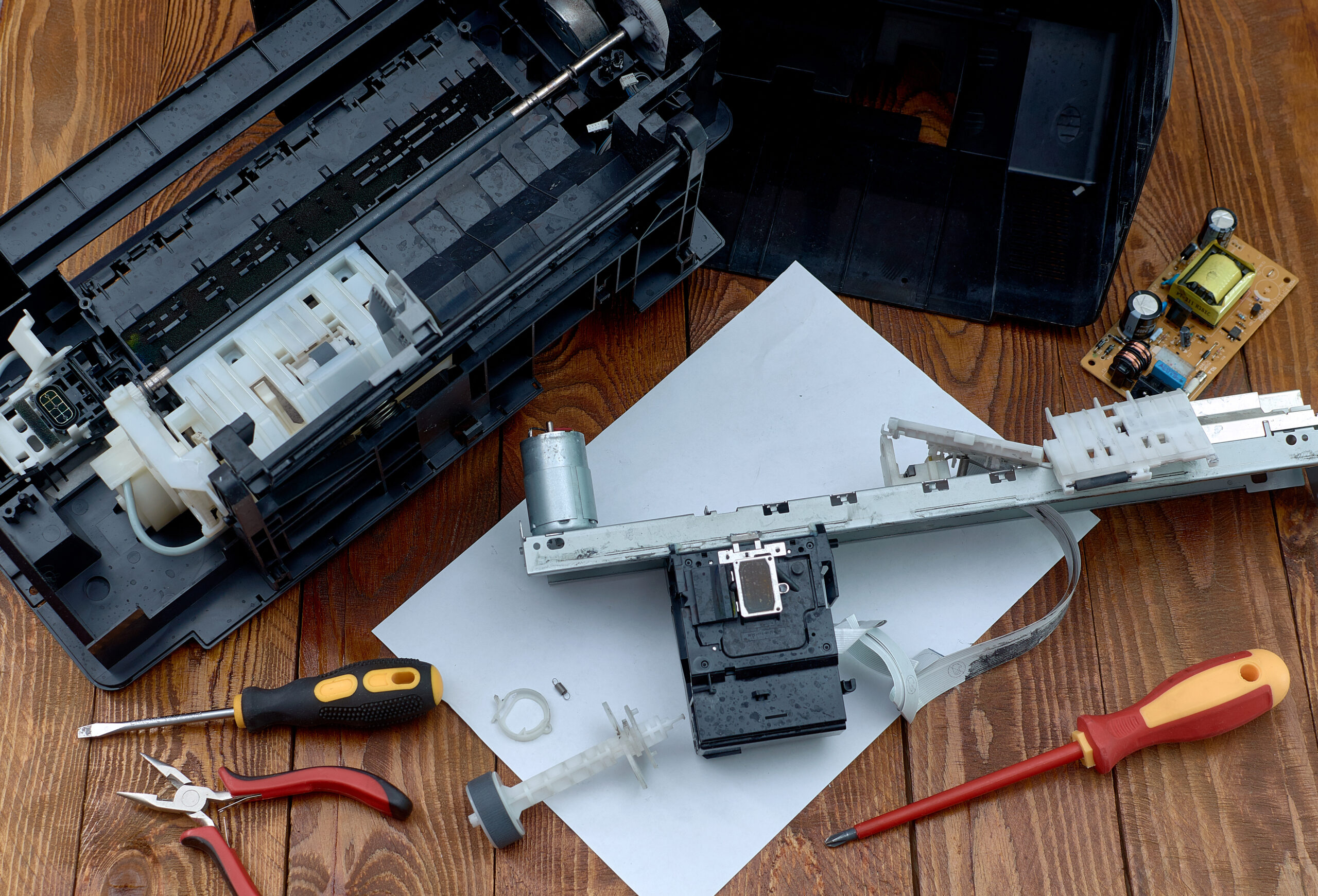

Printhead

The spray nozzle of your inkjet, tiny openings that mist ink onto the page.

Tiny nozzles “write” your image line‑by‑line.

Quick tip: If your photos streak even after a cleaning cycle, the nozzles may be clogged, remove the cartridge and run a manual clean.

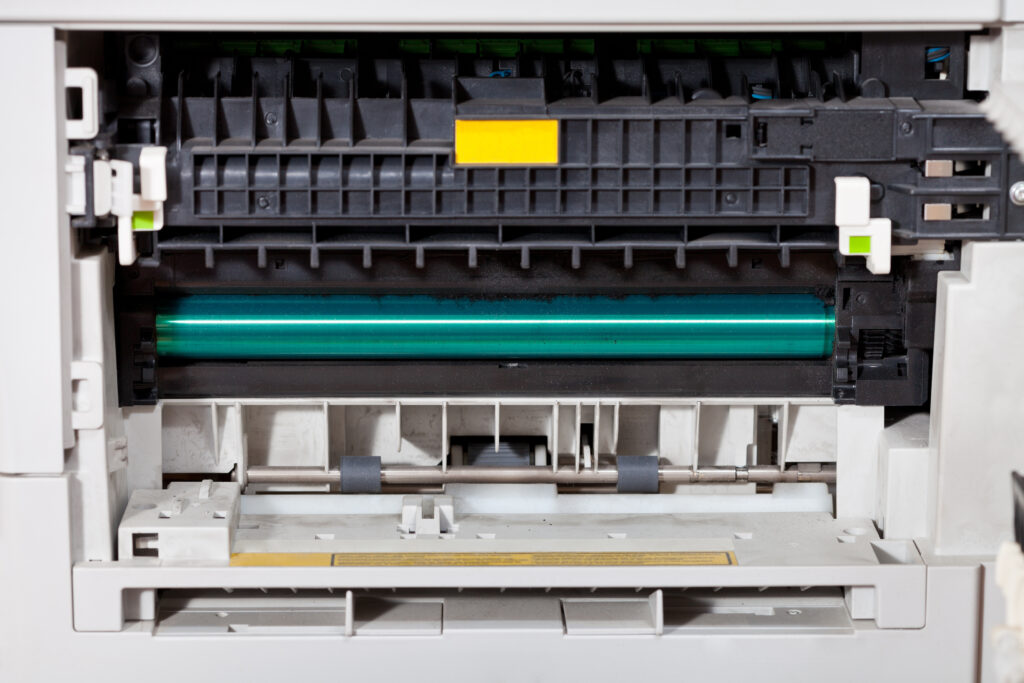

Drum Unit

A light‑sensitive drum, think of a temporary whiteboard.

A laser “draws” your page onto the drum with static electricity (the same cling you feel when pulling laundry from a dryer). The charged image attracts powdery toner, which is then rolled onto the paper.

Color laser printers use four drums: one each for cyan, magenta, yellow, and black (CMYK), so a full drum set can sometimes cost more than the toner cartridges themselves.

Quick fix: Prints look faded or blotchy even with a fresh toner cartridge? The drum’s light‑sensitive coating may be worn out; swapping in a new drum usually brings the contrast right back.

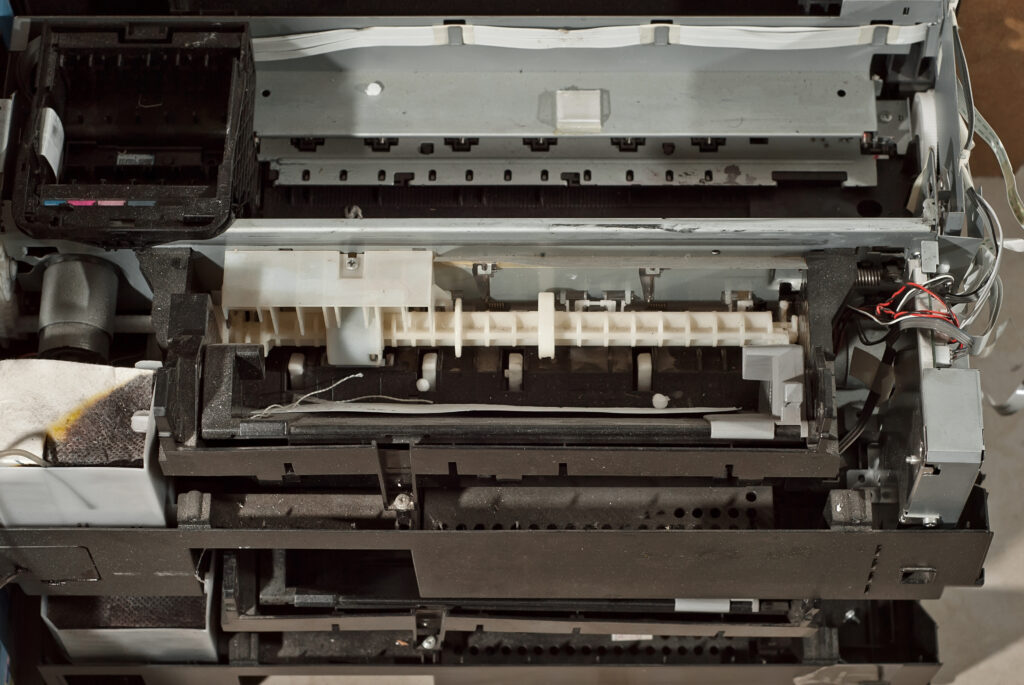

Fuser Assembly

Think of it as a mini laminator, as heated rollers melt and press toner permanently onto the page. Expect 100k–150k pages of life; smudges or ghost images are red flags it’s time to replace.

Transfer Belt / Transfer Roller

The conveyor belt of your color laser printer.

After each drum lays down its layer of toner, the belt carries that full‑color image and “hands it off” to the paper, just like a relay runner passing the baton. Because the same belt touches every color layer, wear shows up as long, repeating streaks that run the length of the page.

Quick test: Print a solid‑color sheet. If the streak appears in the same spot on every color page, your transfer belt is the likely culprit.

Paper Path & Interface Components

- Pickup Roller – The printer’s rubber fingertip.

It grips the top sheet, whether plain paper, envelope, or label, and feeds it into the print path. Clean it with a lint‑free cloth and a dab of isopropyl alcohol if sheets misfeed or multiple pages stick together. - Paper Tray / Cassette – Your paper drawer.

It stores your media, the industry term for anything the printer can print on: letter‑size paper, legal, cardstock, glossy photo sheets, even envelopes. Many printers offer multiple trays so you can keep different sizes or types loaded and switch jobs without stopping to reload. - Control Panel – The printer’s dashboard.

Physical buttons or a touchscreen plus status lights show what the printer is doing, display error codes, and let you run quick maintenance tasks like cleaning cycles or firmware updates.

Printer Supplies: Consumables to Keep On Hand

Toner Cartridge (Laser)

Powdered paint for your laser printer.

Toner is a fine plastic powder that melts and bonds to the page, imagine ironing colored sand into paper. Newer “chemical” toner formulas have smoother, more uniform particles, so lines look sharper and the fuser can run at lower temperatures, saving energy (and your electric bill).

Ink Cartridge (Inkjet)

Liquid color pens for your printer.

Dye inks soak into the fibers like watercolor, giving photos brilliant saturation, while pigment inks sit on the surface like permanent marker, making documents crisp, fade‑ and water‑resistant. Many inkjets keep each CMYK color in its own cartridge, so you replace only the shade you emptied.

Maintenance Kit

Your printer’s 30,000‑mile tune‑up.

This boxed set, typically pickup rollers, a fuser, and transfer parts, refreshes the high‑wear items that keep pages moving smoothly. Installing it at the recommended page count prevents jams and blotches before they start. Check your model’s service page for the right SKU.

Waste Toner Bottle / Container

The printer’s vacuum bag.

It captures the leftover powder the drum and belt can’t reuse. When the little bottle icon flashes, swap it out right away; once full, many printers refuse to print to prevent messy spills

Imaging Kit

Fresh photo film for your laser, sold as a bundle so you don’t miss a piece.

Often called a photoconductor kit, it usually contains:

- New drum unit – the light‑sensitive cylinder that attracts toner.

- Transfer roller (or belt, depending on model) – carries the image from drum to paper.

- Reset chip – tells the printer it has a clean slate.

When to swap: Most kits are rated for 40k–60k pages. Your printer will flash “Replace PC Kit,” or you’ll notice shadowy “ghost” images repeating down the page. Installing the entire kit at once restores sharpness and costs less than buying parts à la carte, plus it keeps you from accidentally double‑buying a drum.

Pro tip: Recycle the spent kit through the manufacturer’s free mail‑back program to keep heavy metals out of landfills.

Bonus Terms to Know

- Yield – Mileage rating for a cartridge.* Industry tests assume 5 % page coverage, roughly one paragraph on a letter page. Heavy graphics are like stop‑and‑go traffic and can chop that number in half.

- OEM (Original Equipment Manufacturer) – Factory‑original supplies from your printer’s brand. They cost more, but guarantee color consistency, perfect fit, and keep your warranty intact.

- Compatible / Remanufactured Cartridges – Aftermarket look‑alikes or professionally rebuilt cartridges. Savings of 20–40 % are common, but quality hinges on the vendor—look for ISO/IEC or STMC certification to avoid leaks and streaks.

- Duplexing Unit – Built‑in page flipper. It automatically prints both sides, trimming paper (and postage) by up to 50 %. Expect a slight speed trade‑off because each sheet loops back through the engine.

- Firmware – Your printer’s brain software. Updates can unlock new features, patch security holes, or, yes, block counterfeit chips. Skim the release notes and back up settings before you click Upgrade.

Maintenance Tips

- Clean rollers and printheads regularly.

- Use genuine or high‑quality compatible supplies.

- Monitor supply levels and replace items proactively.

Need a hand? Applied Innovation’s friendly print pros can spot issues before they snowball, so you can get back to work, jam‑free. Schedule a quick call today!